How To Repair A Circuit Board

Excursion Lath Troubleshooting Guide: 4 Strategies for Identifying Faults

Printed circuit boards (PCBs) are central to nearly every single electronic piece of equipment and machinery manufacturers use in factories today. A PCB's principal job is to connect electrical components, relaying input signals to advisable control actions. Because they're so central to electromechanical operation, PCB failures tin can exist debilitating and need resolution chop-chop.

Not every PCB failure is the same. Different bug bear on boards in unlike ways — from curt circuits to spotty functioning, complete failure, and more. Here are some of the most mutual catalysts for PCB malfunction and failure:

- Burning or burnt components

- Debris or environmental damage

- Historic period-related power issues

- Soldering problems

- Chemical fluid leakage

Not simply does each of these issues stem from a unique goad just each besides causes unique interruptions maintenance and repair technicians demand to properly diagnose during PCB inspections and repairs. To brand sure they are addressing the right components, comprehensive troubleshooting is paramount.

PCB Troubleshooting approaches

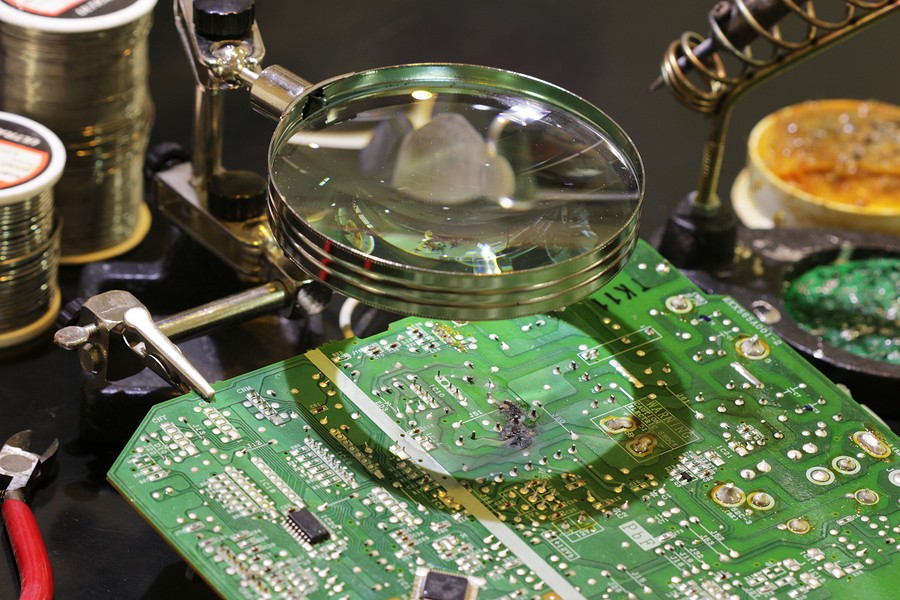

PCB troubleshooting is a delicate procedure non only because the boards themselves are pocket-size in calibration merely because each of the individual components that comprises it is also sensitive. Repair techs must approach PCB maintenance with a keen center for detail and mind for careful handling.

To uncover the reason or reasons backside a PCB failure, information technology's of import to exist methodical in troubleshooting and inspecting. Here are the 4 crucial steps to take — ranging from broad inspection to detailed troubleshooting — to become to the lesser of a PCB malfunction:

- Visual inspections — You tin run into a lot through a visual inspection. Burned or eroded components are the easiest to spot, which signal overheating issues or chemical fluid leakage as reasons for malfunction. You can likewise identify missing components, indicating a flawed or defective board. Finally, clean away droppings before probing the board deeper for issues.

- Physical inspections — With the board under load, a concrete inspection may yield additional insights. Hot spots are easy to experience, which tin can point potential burnt components that may not be visually identifiable. Probing with an oscilloscope tin can also help discover impedance issues resulting from age-related ability issues.

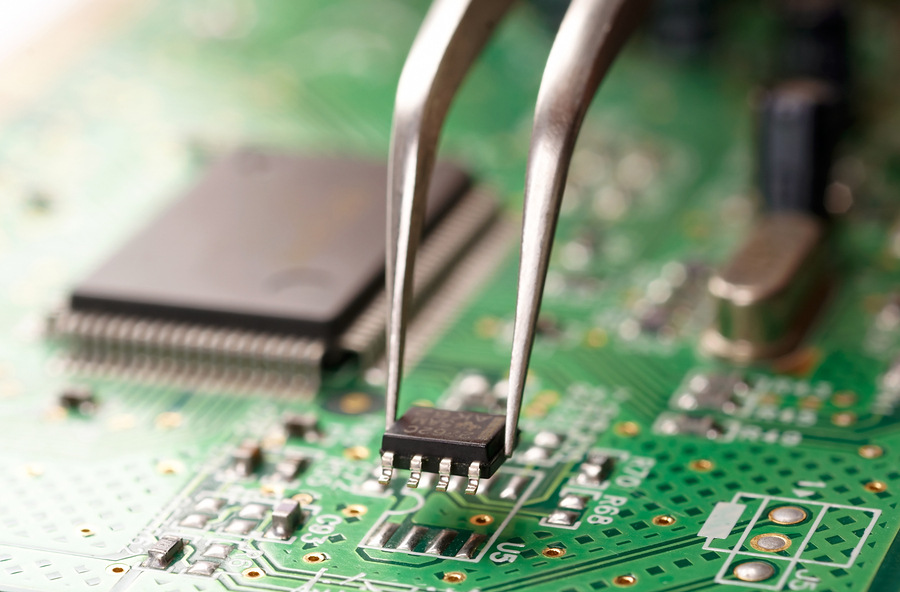

- Component testing — Delving deeper into the PCB'south many components, you can examination the integrity of batteries, capacitors, resistors, inductors, diodes, switches, and transistors. Utilise a multimeter to compare values to factory standards to spot discrepancies. Oft, information technology's these individual components that neglect and eventually atomic number 82 to larger failures of the entire PCB.

- Integrated circuit testing — A concluding phase of PCB troubleshooting involves testing integrated circuits (ICs). An oscilloscope too comes in handy here. Unfortunately, information technology can exist difficult to test ICs, depending on how many are nowadays on a PCB or the nature of the circuit itself. The all-time approach is to identify a known skillful excursion and test all ICs confronting it to recognize problematic ones.

Post-obit these 4 steps helps ensure techs give complete and thorough attention to each excursion lath during troubleshooting. The methodical nature of this approach also allows repair techs to assess all the common causes of PCB failure so they don't overlook issues.

What to do with a failed PCB

What happens if your PCB suffers a catastrophic failure? According to the United States Ecology Protection Agency (EPA), at that place is an amalgam of hazardous parts within PCBs that necessitate proper disposal. Turn over PCBs to a recognized recycling dominance so professionals can properly strip them of their materials and salvage their parts.

Similar whatever part of industrial mechanism that's worked tirelessly each day, PCBs demand a little attention and some minor repairs to stay functional. Heading off issues with a thorough inspection means preventing the type of catastrophic failure that might warrant recycling!

PCB failures waste no time in causing trouble for your machinery. Contact the professionals at Global Electronic Services for all your industrial electronic, servo motor, AC and DC motor, hydraulic, and pneumatic needs — and don't forget to like and follow u.s. on Facebook!

Source: https://gesrepair.com/circuit-board-troubleshooting-4-strategies-identifying-faults/

0 Response to "How To Repair A Circuit Board"

Post a Comment